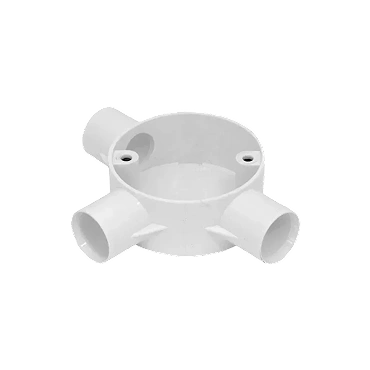

VIP PVC Surface Junction Box with Lid and Screw

VIP PVC Surface Junction Box with Lid and Screw

ಉಪಲಬ್ದವಿದೆ

ಪಿಕಪ್ ಲಭ್ಯತೆಯನ್ನು ಲೋಡ್ ಮಾಡಲು ಸಾಧ್ಯವಾಗಲಿಲ್ಲ

Product Highlights

Quick Answer: What is VIP PVC Surface Junction Box used for?

VIP PVC Surface Junction Box is a UPVC electrical junction box with lid and screw, designed for surface-mounted wall conduiting to safely house wire connections and splices with fire retardant properties.

- Material: UPVC (Unplasticized Polyvinyl Chloride)

- Mounting Type: Surface mounting for wall conduiting

- Includes: Lid and screw for secure closure

- Compatible Sizes: 19mm, 20mm, and 25mm conduit

- Configurations: 3-way and 4-way with 90-degree socket openings

- Colors: Black, Grey, and White

- Standard: Conforms to IS 3419 specifications

- Safety: FR (Fire Retardant) properties

Product Description

VIP PVC Surface Junction Box is a precision-engineered UPVC electrical enclosure manufactured by VIP Extrusions using automatic injection molding technology, designed specifically for surface-mounted wall conduiting applications. This junction box provides safe and accessible housing for electrical wire connections, splices, and terminations in exposed conduit installations.

Available in 3-way and 4-way configurations with 90-degree socket openings, this junction box integrates seamlessly with 19mm, 20mm, and 25mm conduit systems. The fire retardant UPVC construction ensures safety compliance while offering lightweight installation, corrosion resistance, and long-term durability. Each box includes a secure lid with screw fastening to protect connections from dust, moisture, and accidental contact, making it ideal for residential, commercial, and industrial surface wiring applications.

Technical Specifications (Quick Reference)

| Specification | Details |

|---|---|

| Material | UPVC (Unplasticized Polyvinyl Chloride) |

| Mounting Type | Surface mounting for wall conduiting |

| Conduit Compatibility | 19mm, 20mm, and 25mm diameter |

| Socket Configurations | 3-way and 4-way with 90-degree openings |

| Manufacturing | Automatic injection molding |

| Standard Compliance | IS 3419 specifications |

| Safety Rating | FR (Fire Retardant) |

| Color Options | Black, Grey, White |

| Includes | Lid and screw |

Recommended Applications

- Surface Wiring Systems: Exposed conduit installations in basements, garages, workshops, and utility areas

- Industrial Facilities: Factories and warehouses where surface-mounted conduit is standard practice

- Commercial Renovations: Retrofit electrical installations without wall demolition

- Outdoor Covered Areas: Covered patios, carports, and semi-outdoor spaces (with proper weatherproofing)

- Temporary Installations: Construction sites and temporary power distribution systems

- Circuit Branching: Distributing power and lighting circuits in multiple directions with 3-way or 4-way configurations

Installation Guidelines

- Plan Junction Location: Mark box position at conduit intersection points; ensure accessibility for future maintenance

- Mount Box to Wall: Secure the junction box directly to wall surface using appropriate screws and anchors; ensure box is level and firmly attached

- Connect Conduits: Run surface conduits to the box socket openings (3-way or 4-way as needed); use appropriate saddles to support conduit runs

- Pull and Connect Wires: Feed wires through conduits into the box; make connections using wire nuts or terminal blocks; leave adequate wire length for future work

- Secure Lid: After completing all wire connections, attach the lid using the provided screw; ensure tight closure to protect connections from environmental exposure

FAQs

1) What is the difference between surface and deep junction boxes?

Surface junction boxes mount directly on wall surfaces for exposed conduit installations, sitting proud of the wall. Deep junction boxes are designed for concealed installations within walls or slabs, sitting flush with the surface. Surface boxes are ideal for basements, garages, and industrial settings where exposed wiring is acceptable or preferred.

2) Why choose PVC over metal junction boxes?

PVC junction boxes offer several advantages: lighter weight for easier installation, corrosion resistance in damp environments, no grounding required (non-conductive), lower cost, and easier to work with. However, metal boxes provide superior fire resistance and impact protection, making them better for high-risk or heavy-duty applications.

3) Should I choose 3-way or 4-way configuration?

Choose based on your conduit layout: 3-way boxes have three socket openings at 90 degrees, suitable for T-junctions or simple branching. 4-way boxes have four openings, ideal for cross-junctions or more complex circuit distributions. Consider future expansion—a 4-way box provides flexibility for potential circuit additions.

4) Can I use this junction box outdoors?

While UPVC is weather-resistant, standard surface junction boxes are designed for dry or damp indoor locations. For outdoor use, ensure the box has appropriate weatherproof rating and use weatherproof gaskets, conduit seals, and proper lid sealing. For fully exposed outdoor locations, consider boxes specifically rated for wet locations.

5) Do I need to ground a PVC junction box?

No, PVC junction boxes do not require grounding because they are non-conductive. However, you must still run a ground wire through the box to maintain circuit grounding continuity. The ground wire connects to outlets, switches, and metal fixtures, but not to the PVC box itself.

6) How do I ensure the lid stays secure in high-vibration areas?

For vibration-prone environments, use thread-locking compound on the lid screw to prevent loosening over time. Alternatively, consider upgrading to a lid with multiple screw points or a snap-lock design. Periodically inspect and retighten the screw during maintenance to ensure continued protection of wire connections.

7) What wire capacity can I expect in these junction boxes?

Wire capacity depends on box size and configuration. Generally, 19mm boxes accommodate 4-8 wire connections, while 25mm boxes handle 8-12 connections depending on wire gauge. Always follow NEC/IEC box fill calculations based on wire size and number of conductors to prevent overcrowding and ensure safe heat dissipation.

Why Buy from HomeRun?

- Authentic VIP Hardware: Verified genuine products conforming to IS 3419

- Complete Conduit System: Compatible with VIP conduit pipes, bends, and accessories

- Bangalore Fulfilment: Quick local availability

Returns & Exchange Policy

- Return within 72 hours of delivery for:

- Damaged or defective product

- Wrong or missing item

- Product cannot be returned once installed or used

- Refer to Refund Policy for complete details