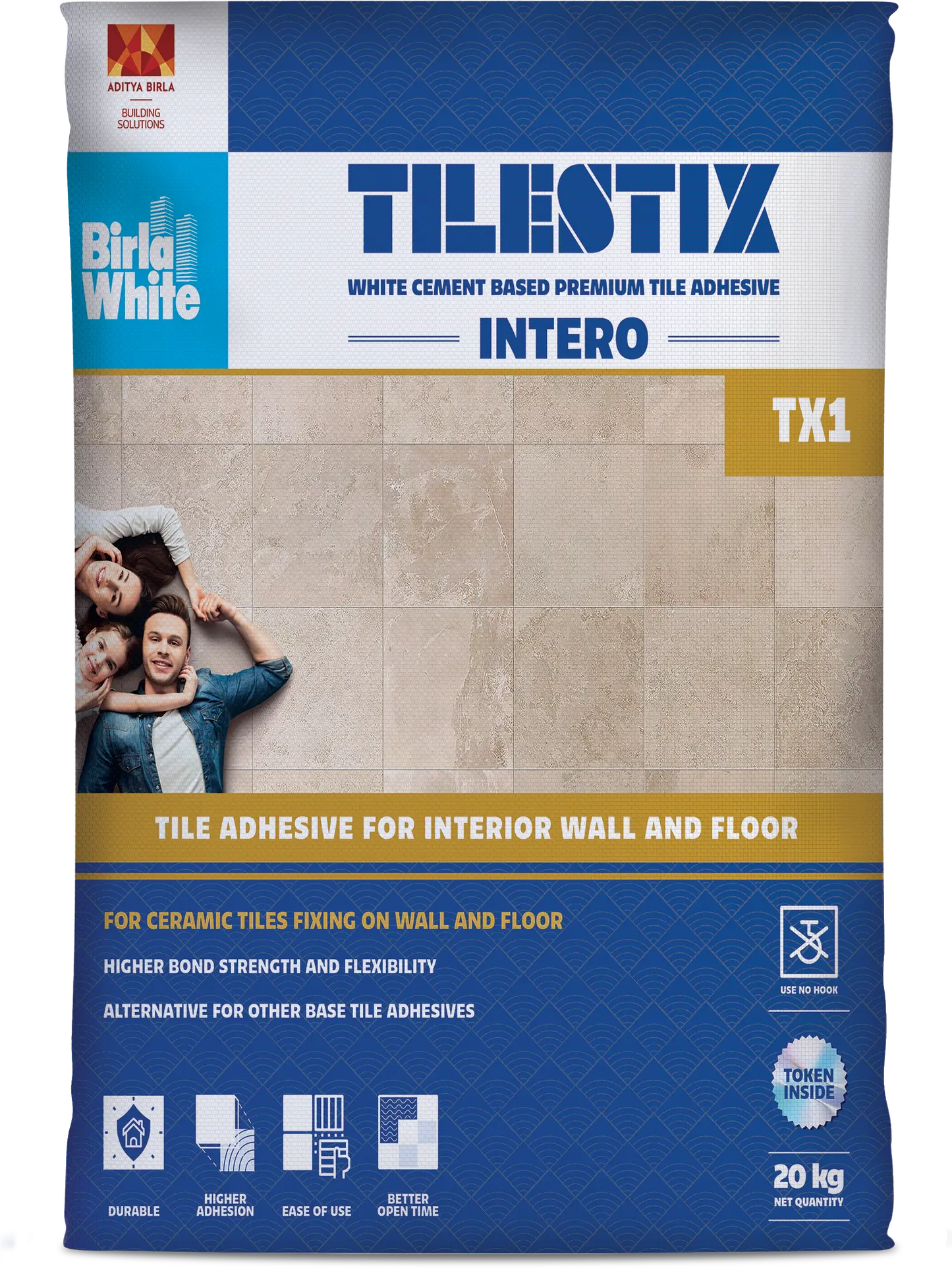

Birla White TX1 Tile Adhesive,White, 20 kg Bag

Birla White TX1 Tile Adhesive,White, 20 kg Bag

In stock

Couldn't load pickup availability

Product Highlights

Quick Answer: What is Birla White TX1 Tile Adhesive used for?

Birla White TX1 Tile Adhesive is a polymer-modified cement-based tile adhesive, designed for ceramic, vitrified, porcelain, and marble tiles, white base reduces color show-through under light tiles.

- Type: Polymer-Modified Cement-Based Adhesive

- Color: White

- Packaging Size: 20 kg Bag

- Suitable For: Ceramic, vitrified, porcelain, marble

- Benefit: White base prevents color show-through

Product Description

Birla White TX1 Tile Adhesive is a polymer-modified cement-based tile adhesive manufactured by Birla White, engineered for fixing ceramic, vitrified, porcelain, and marble tiles. The white base formulation reduces color show-through under light tiles, ensuring premium aesthetic results.

Ideal for residential and commercial tiling projects, Birla White TX1 offers superior bonding strength and workability. The white formulation is particularly beneficial for light-colored, translucent, or premium tiles where grey adhesive might affect appearance, providing professional results for high-end tiling projects in Bangalore.

Technical Specifications (Quick Reference)

| Specification | Details |

|---|---|

| Product Type | Polymer-Modified Cement-Based White Adhesive |

| Color | White |

| Packaging | 20 kg per bag |

| Suitable Tiles | Ceramic, vitrified, porcelain, marble |

Recommended Applications

- Light-Colored Tiles: White base prevents dark shadows on light or translucent tiles

- Marble Installations: Ideal for marble tiles where color preservation is important

- Porcelain Tiles: Excellent bonding for porcelain tile installations

- Vitrified Tiles: Suitable for vitrified tile fixing on floors and walls

- Ceramic Tiles: Perfect for ceramic tile applications in residential and commercial spaces

- Premium Installations: Professional choice for high-end tiling projects

Installation Guidelines

- Surface Preparation: Ensure surface is clean, level, and properly prepared for tile installation

- Mixing: Add Birla White TX1 powder to clean water and mix thoroughly to smooth white consistency

- Application: Apply white adhesive using appropriate notched trowel for tile size

- Tile Placement: Press tiles firmly; white adhesive won't show through light tiles

- Curing: Allow 24-48 hours curing before grouting; avoid foot traffic during curing

FAQs

1) Why use white tile adhesive instead of grey?

White tile adhesive prevents color show-through on light-colored, translucent, or marble tiles. Grey adhesive can show through and darken the appearance of light tiles, while white maintains the true color and brightness of premium tiles.

2) Is Birla White TX1 suitable for marble tiles?

Yes, Birla White TX1 is ideal for marble tiles. The white formulation prevents dark shadows that would be visible through translucent marble, while the polymer-modified bonding ensures secure installation of marble tiles.

3) Can I use this for porcelain tiles?

Yes, Birla White TX1 is suitable for porcelain tiles. The polymer-modified formulation provides excellent bonding to low-porosity porcelain tiles, ensuring durable installations on floors and walls.

4) What is the coverage of one 20 kg bag?

Coverage depends on tile size, surface condition, and trowel notch size. Typically, one 20 kg bag covers approximately 5-8 square meters for standard tiles. Larger tiles may require more adhesive.

5) Is Birla White TX1 suitable for vitrified tiles?

Yes, Birla White TX1 is excellent for vitrified tiles. The polymer-modified formulation provides superior bonding to low-porosity vitrified tiles, while the white color is ideal for light-colored vitrified tile installations.

6) Can I use this for wall tiling?

Yes, Birla White TX1 can be used for wall tiling. The adhesive provides good bonding on vertical surfaces, making it suitable for wall tile installations in residential and commercial interiors.

7) How long should I wait before grouting?

Allow 24-48 hours curing time before grouting, depending on temperature, humidity, and tile size. Ensure adhesive has fully set and tiles are firmly bonded before applying grout.

Why Buy from HomeRun?

- Authentic Birla White Products: Verified genuine products from authorized distributors

- Fresh Stock Guarantee: All adhesive within optimal shelf life for maximum bonding performance

- Bangalore Fulfilment: Quick local availability with express delivery across Bangalore

Returns & Exchange Policy

- This product is non-returnable.

- Replacement available within 24 hours of delivery for:

- Damaged or defective product

- Wrong or missing item

- Product cannot be returned once installed or used

- Refer to Refund Policy for complete details